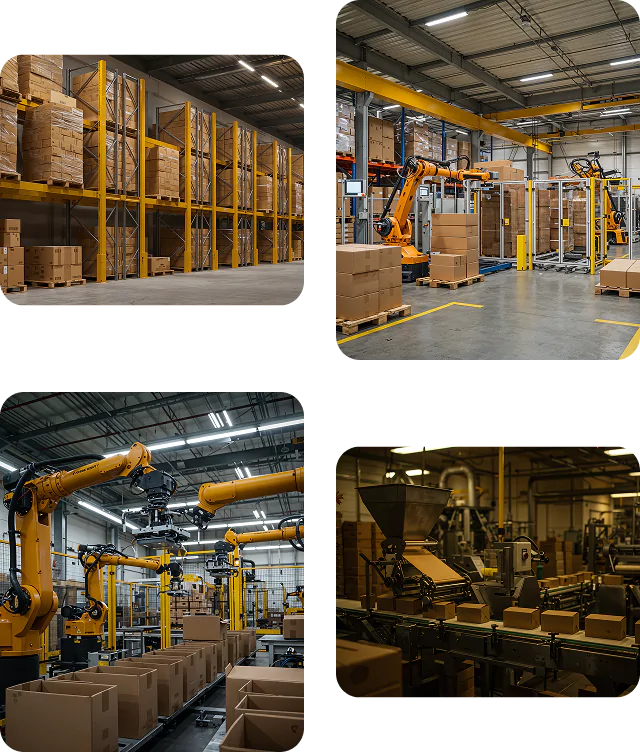

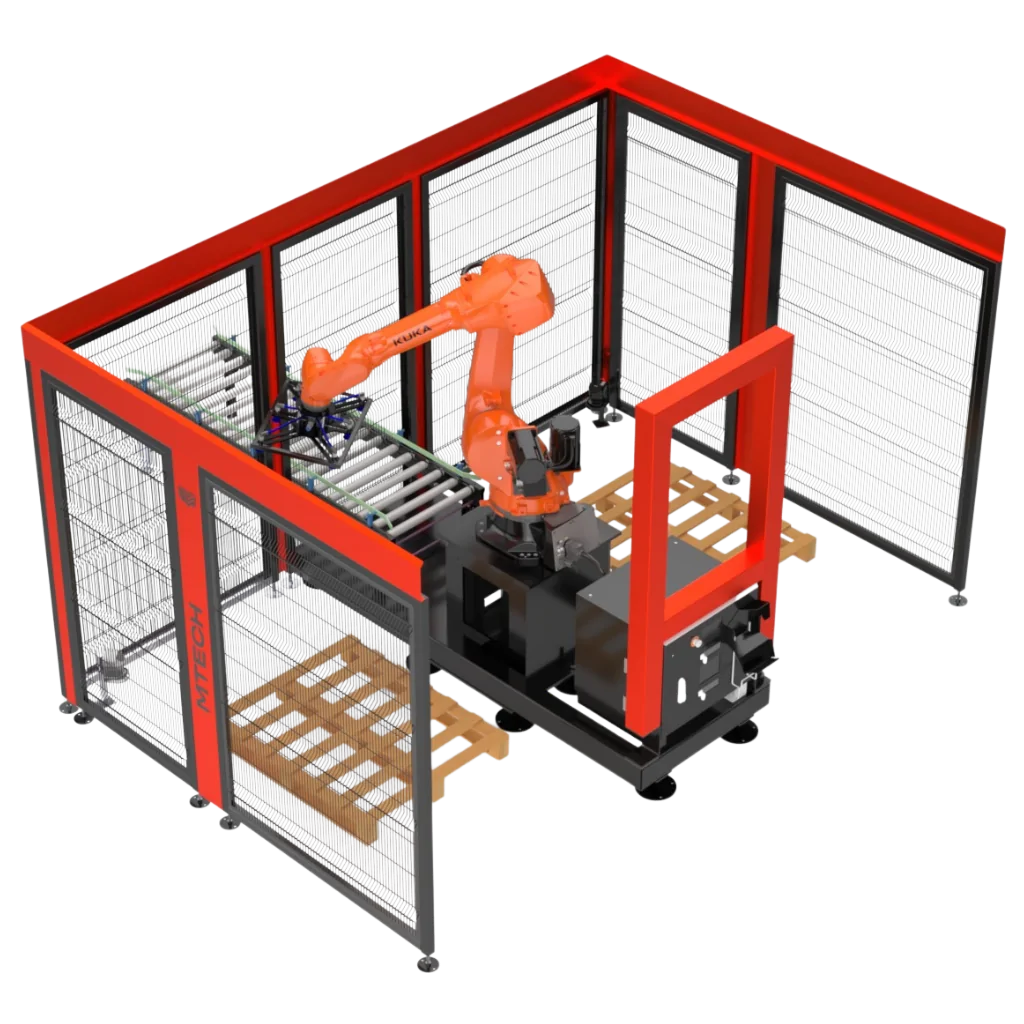

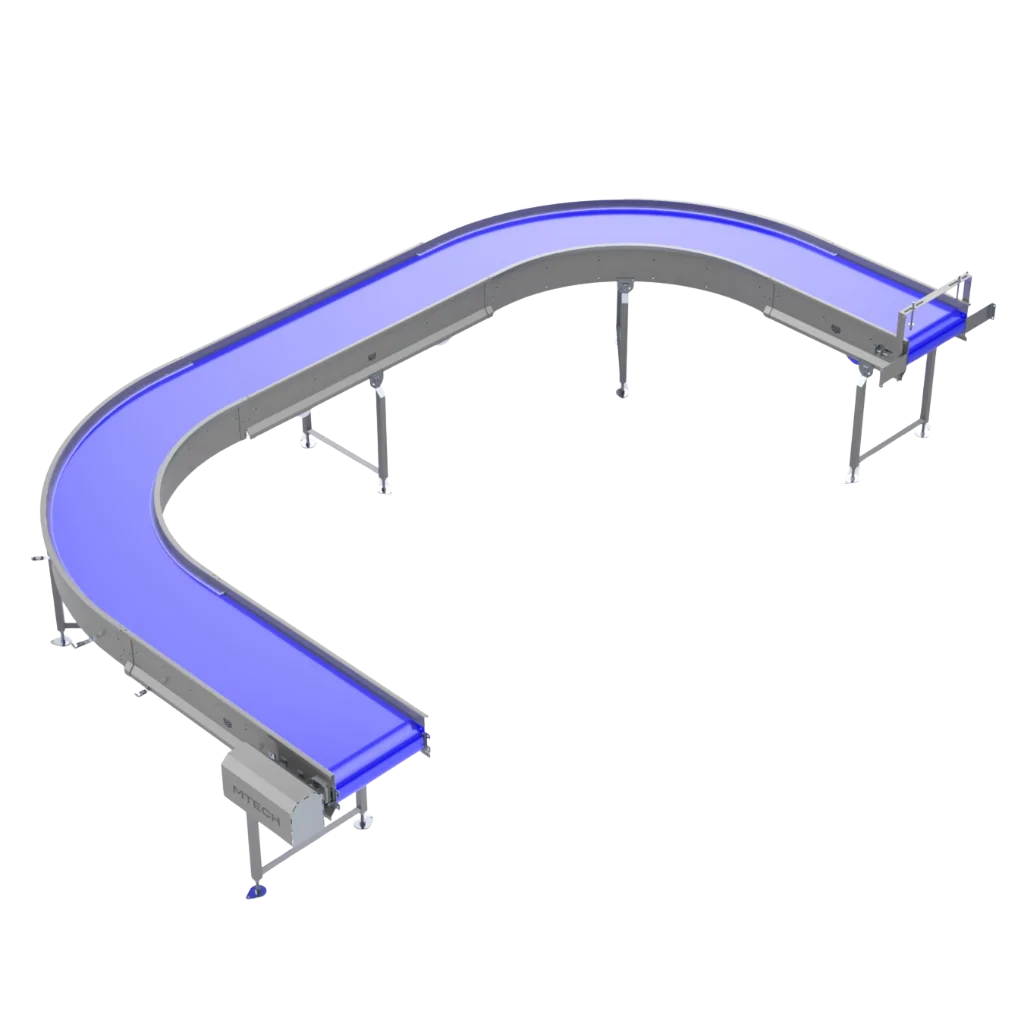

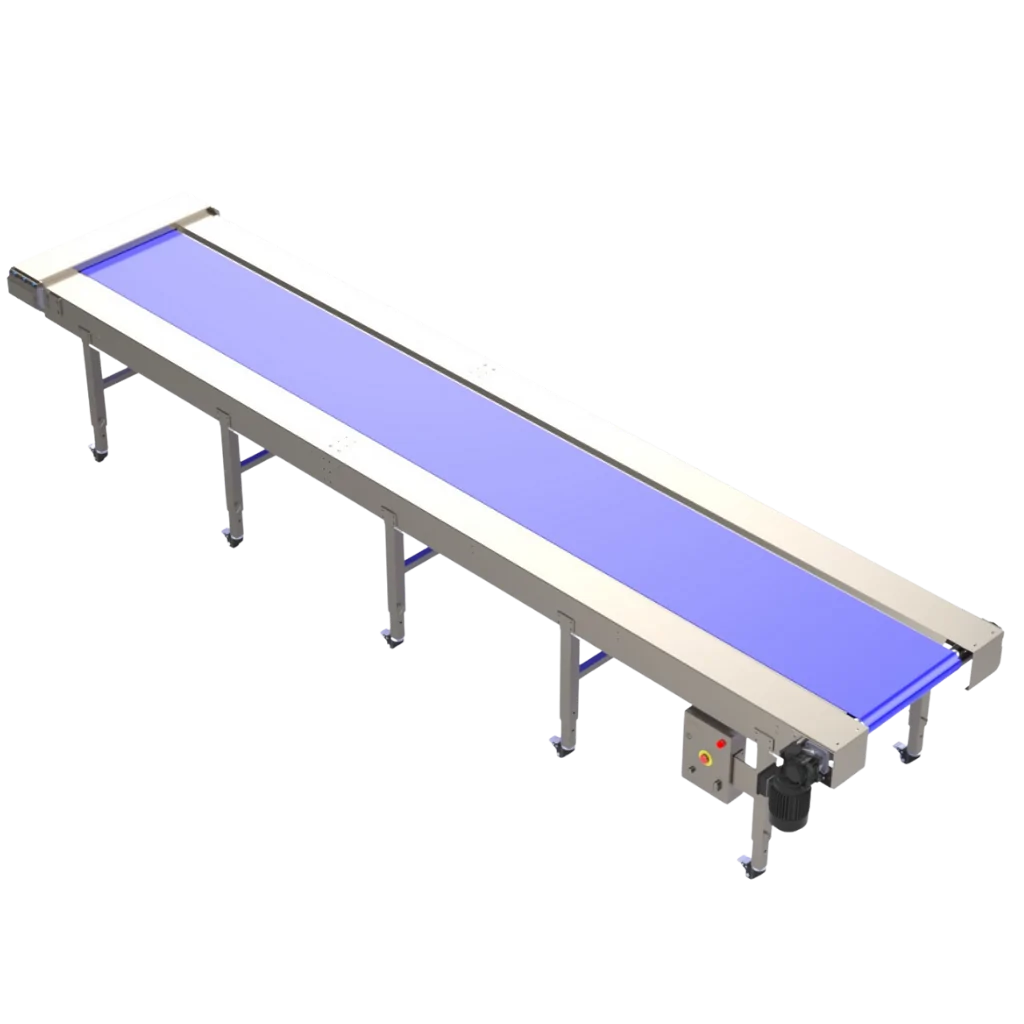

MTECH's Case Packing Line was developed to automate the final packaging process with agility, safety, and standardization. Our systems adapt to different types of packaging, such as cartridges, jars, pouches, and trays, promoting efficient, clean packaging that is synchronized with the production flow.

Each piece of equipment is designed to integrate into your factory layout, meet your product requirements, and minimize manual effort.

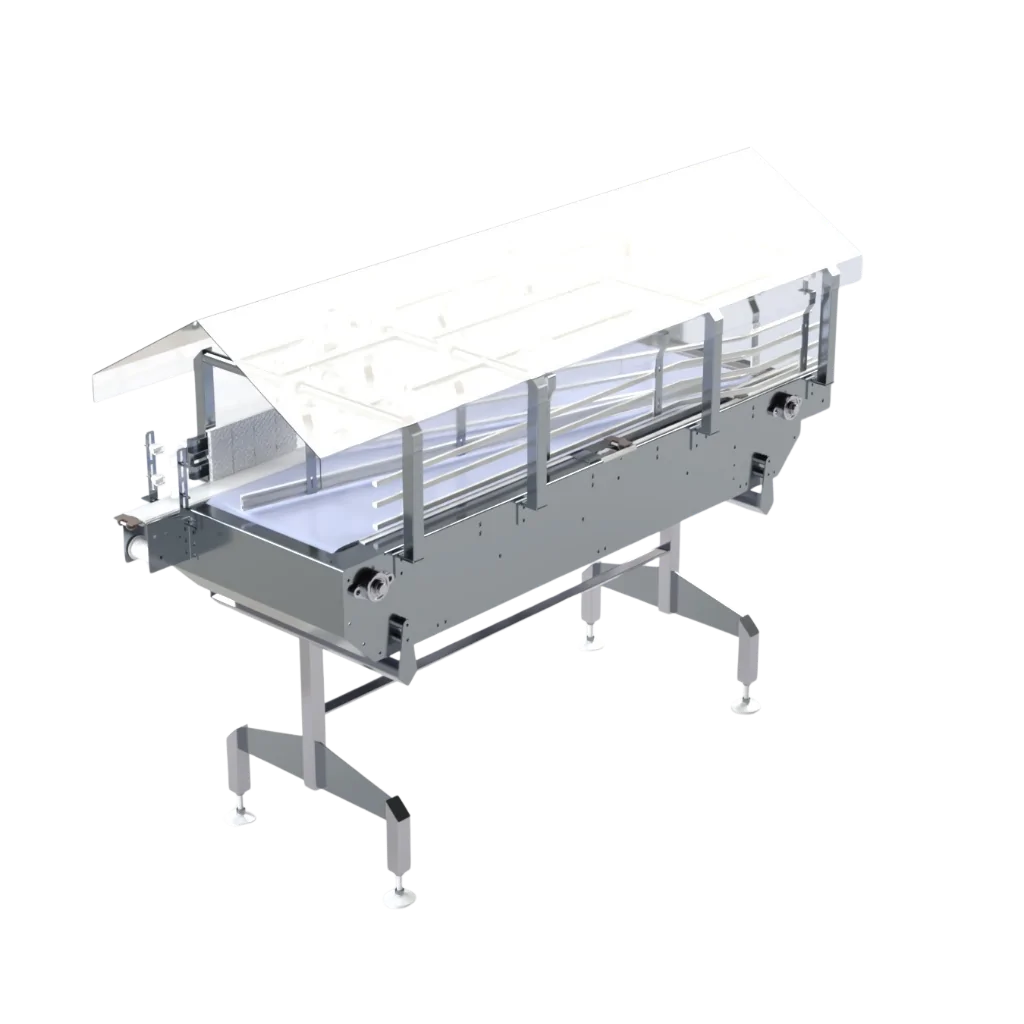

Our case packers operate with precision on packages of different sizes and materials, without loss of speed.

We automate repetitive and cumbersome tasks, promoting ergonomics, productivity and a lower risk of failure.

We design equipment to connect seamlessly to your production structure, without rework or improvised adaptations.

Made with durable materials and an easy-to-clean finish, ideal for food production environments.

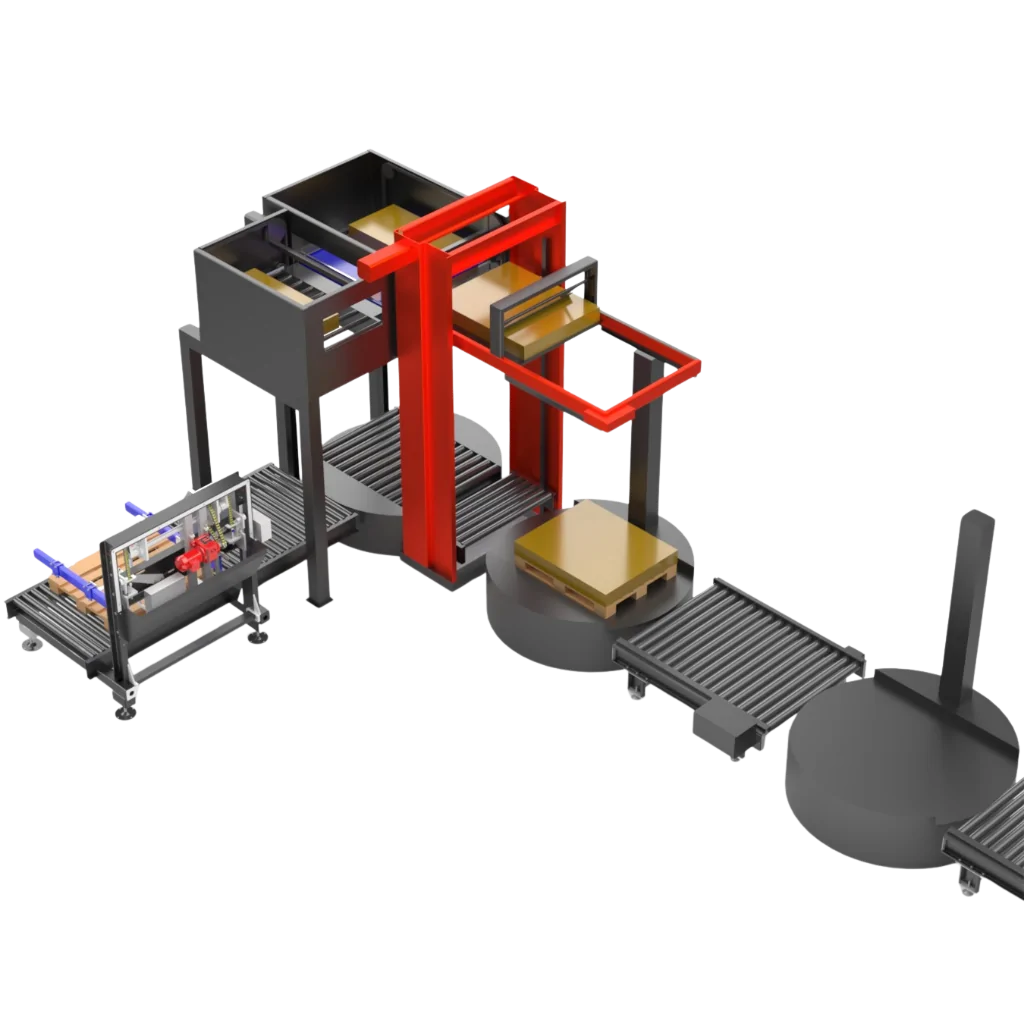

We develop boxing systems compatible with a wide range of formats used in the food industry. Our equipment ensures precise handling, stable packaging, and higher line closing performance.

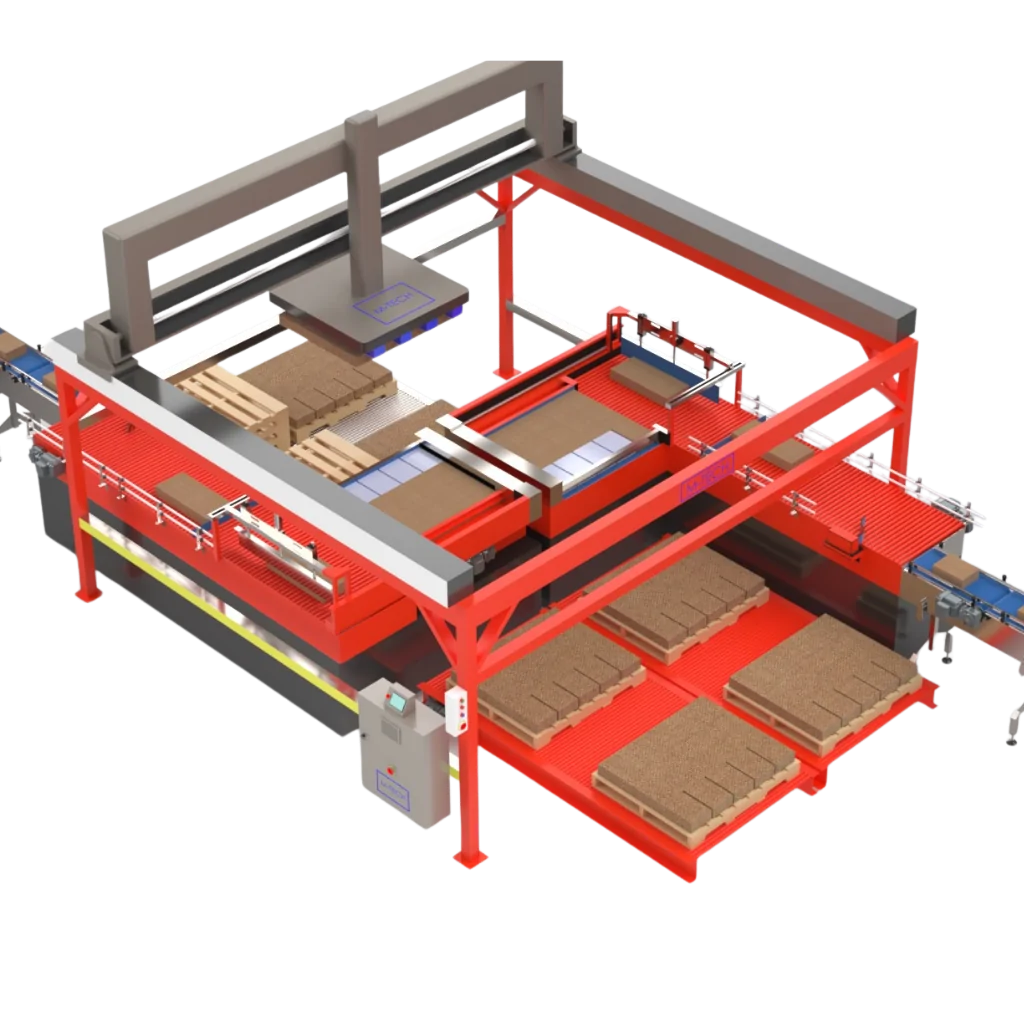

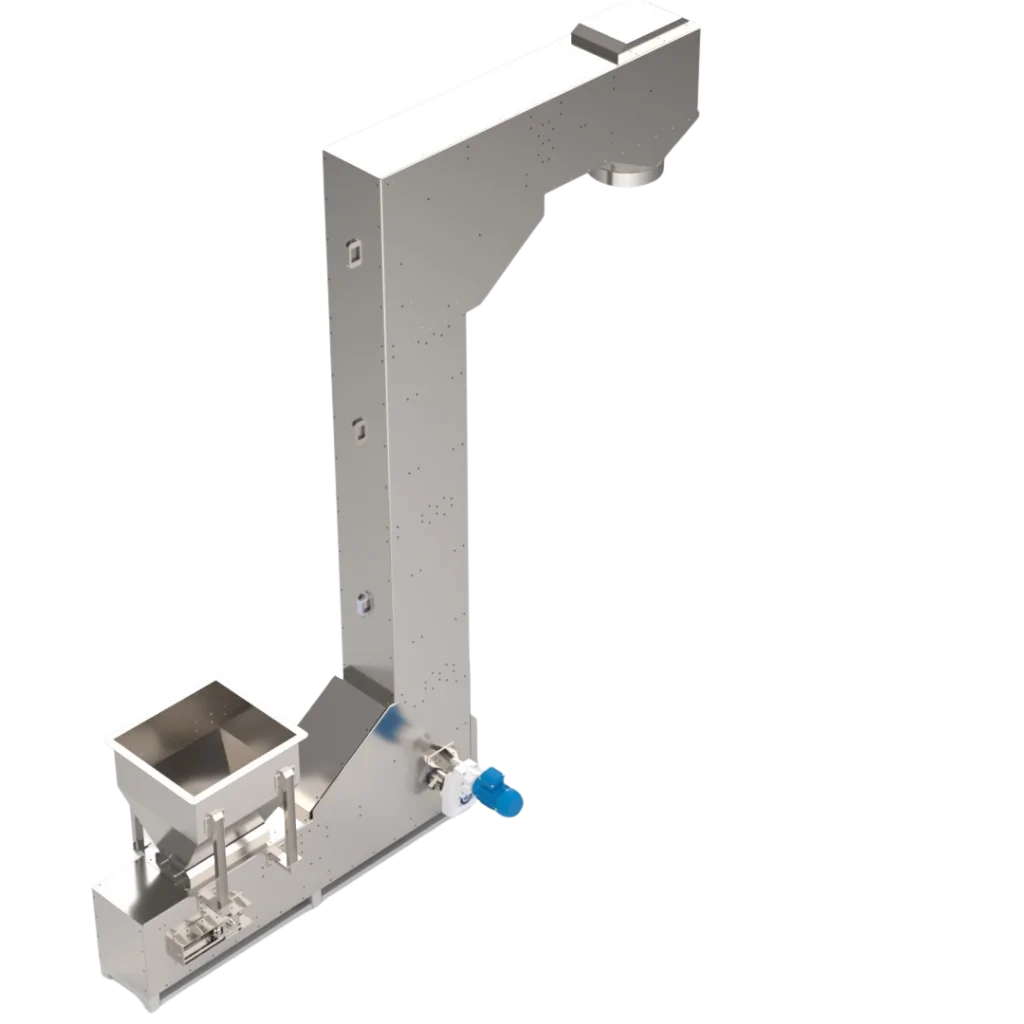

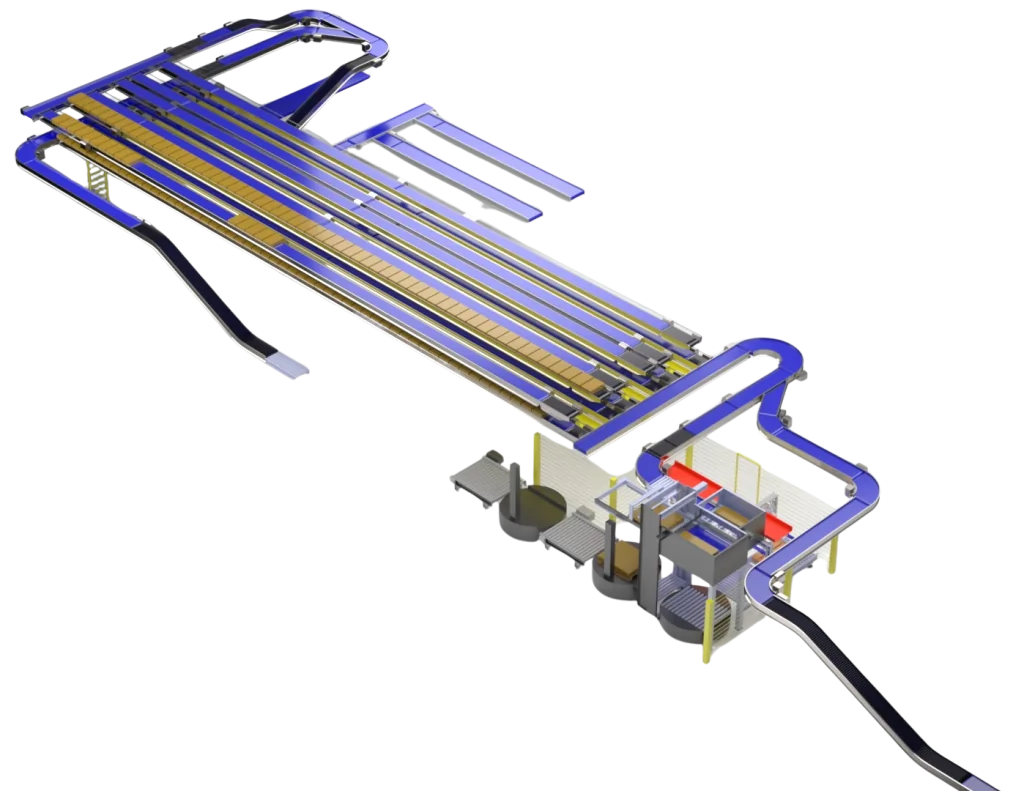

Automatic palletizing for multiple boxes simultaneously.

The system accumulates the largest possible number of boxes according to the physical space available at the customer's disposal.

Each level forms a full pallet per layer. When the accumulation sensor is triggered, confirming that the correct number of boxes for a pallet has been reached, the boxes are released to the palletizer, where automatic palletizing occurs, capable of palletizing up to 1,100 boxes per hour.

"MTech conveyor belts have changed our production routine. They've become much more agile and reliable.

“I really liked the service. The team understood our needs and delivered exactly what we asked for.”

"Robust, easy-to-clean, and high-performance equipment. It was a great choice to work with MTech."

“After we installed the conveyor belts, we were able to reduce downtime and increase productivity.”

"Besides the quality of the machines, MTech always provides quick support when we need it. That makes all the difference."

"We chose MTech because of their experience in the food industry. It was the right decision, with modern and reliable equipment."

"The investment paid off quickly. The line became more efficient and cost-effective."

"Everything was delivered on time and exactly as we agreed. It's great to be able to count on a reputable company like MTech."

"The treadmills fit well in our space and are easy to maintain. I recommend MTech without hesitation."

Developed by: